Asianstar: Professional CNC Machining Supplier

From year of 2005, Asianstar Company establish the CNC Machining Factory in Guangdong Province, China.

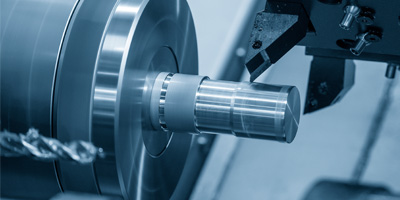

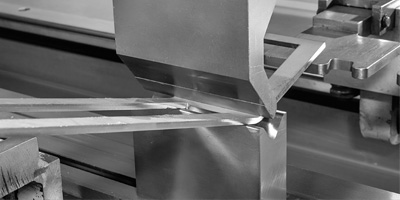

We mostly provide CNC Turning, Milling, Drilling, Grinding, and Multi Machining processes service on various materials.

With the Belief of becoming a key supplier in the supply-chain of Precision Components, we strictly control our product quality, keep high precision on our components production, buildup the whole-process QC System and submit the satisfaction for every order.

By long term development, we have buildup partnership with world-wide clients, supporting our partners in Designing, Optimizing, Producing and Testing on each type of components.

We mostly provide CNC Turning, Milling, Drilling, Grinding, and Multi Machining processes service on various materials.

With the Belief of becoming a key supplier in the supply-chain of Precision Components, we strictly control our product quality, keep high precision on our components production, buildup the whole-process QC System and submit the satisfaction for every order.

By long term development, we have buildup partnership with world-wide clients, supporting our partners in Designing, Optimizing, Producing and Testing on each type of components.

OUR CNC MACHINING SERVICES

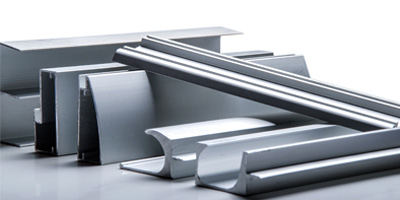

CNC MACHINING MATERIALS ON METAL AND PLASTIC

INDUSTRIES OUR CNC MACHINING SERVE FOR

Car

Motorcycle

Machinery

Lock Cylinder

Bicycles

Watercraft

Robots

Medical Devices

Signal Receiving Devices

Watercraft

Optical Devices

Sporting Equipment

Beauty

Lighting

Furniture

Electronic

Sporting

Semiconductor

WHY CHOOSE US

Premium Quality

Our High Quality Facilities and Full-Process QC System control every work-piece in perfect result, from the structure to accuracy and surface performance are all well done.

Multiple Processes

We have a variety of machining processes, such as Turning, Milling, Drilling, Grinding, and also we have extrusion, fabrication and surface post-treatments to carry out the end finished product

Competitive Price

With our high efficiency equipment, engineers will choose best processing solution each work-piece, considering the cost to the bottom and benefit our clients with Good Price

Lead time Guarantee

We use ERP system to schedule our production plan to make sure all the orders can be submitted within fast lead time. Prototyping Team support hurry projects in advance if necessary

Long Term Development and Achievements

Asianstar aims to become world-wide professional digital manufacturing partners for our clients. Bring client’s ideas and designing into reality, carrying out the work-piece by specializing solutions of multi-processes.

From year 2005 until now, we are serving clients from USA, EURO, JAPAN, KOREA, ASIAN, MID EAST, etc.

We have clients more than 3500 companies and most of them become our long term partner; supporting clients from Designing to Production, Assembly and Quality Controlling...

We have production area of 2’500SM with Turning Machines and Milling Machines and Swiss Type Machines and Other Machining Facilities.

Our team includes Engineers 35 Specialists, Labors and Sales 80 Persons, all production are schedules two shifts daily.

Now we are working for many huge brands, such as VW, Rockwell, Stanley, Husco, etc...

3500+

Customers

2500㎡

Production Area

100000+