Yamaha's R1 is an outstanding bike, so when it came time to cover it up, you might have started out with something plain. But your racing dreams don't end there. So you wanted your R1 to show off a little more than just a [patch]. That's where we come in with this cnc aluminum crankcase cover plug that's intended for your Yamaha YZ426F 00-02 bike

The Yamaha R1 is a great motorcycle and one of the best motorcycles ever made by Yamaha. It has been around since 2005 and has an estimated production run of over 400,000 units. The 2006-2009 model year saw significant changes to the engine, chassis, and more. This included the introduction of new colors (red), colors on the wheels (black), and an aluminum swingarm cover plate that was inspired by their race bikes' covers (chrome).

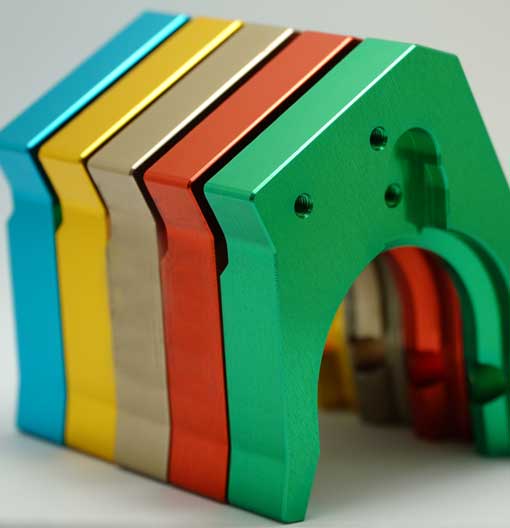

cnc aluminum crankcase cover plug new for yamaha yz426f 00-02