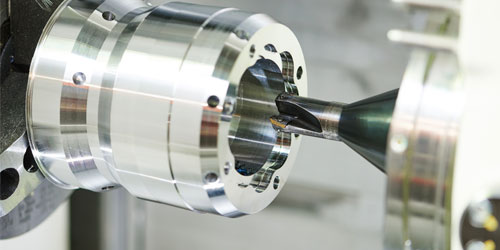

CNC Turning and Milling

Asianstar provide CNC Turn-Mill Machining Service on complicated components at tight tolerance, supporting clients’ various designing into reality.

What is CNC Turning-Milling

CNC Turning-Milling machining is a manufacturing process that uses computer numerical control (CNC) technology to operate a machining center. This process allows the production of complex parts with a high accuracy and repeatability because the turning and milling processes are finished on same machine by one-time jig.

For this efficiency and accuracy reason, CNC Turning-Mill machining is often used in the production of automotive, medical, aerospace and electronic parts.

How Does CNC Turning-Milling Work

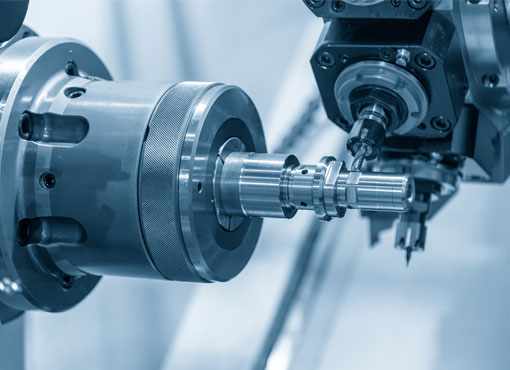

CNC turn-mill machining is equipped with a lathe spindle and a milling spindle, allowing it to perform both operations simultaneously in sequence.

The turning-milling process begins by loading a raw material, metal or plastic, into the machine.

Once the program is loaded, the machine tool begins to rotate the material and move the cutting tool along the desired path. The lathe spindle is used for turning operations, such as creating cylindrical shapes or contours, while the milling spindle is used for milling operations, such as creating holes or slots in the material.

Asianstar Professional CNC Turning and Milling Service

Asianstar Company offers a comprehensive CNC Turning-Milling Service for a wide range of industries. Our skillful engineers can provide precision complex components, with a focus on quality and efficiency.

Our CNC Turning-Milling service includes:

1/ Precision machining of parts and components using turn-mill equipment;

2/ Tight tolerances and consistent quality by one-time jig;

3/ High-speed machining capabilities for increased efficiency;

4/ Customized solutions to meet clients complex needs;

These services can be useful for a wide range of applications, special for complex, precision-machined parts for industries such as aerospace, automotive, and medical devices, etc.

Advantages of Asianstar CNC Turning and Milling Service

Flexible Facilities

Asianstar has turning-milling machines of multi axis allow us to produce wide ranges complex parts, workable on different types of materials

High Quality

Asianstar QC system and tools, gauges, pins, concentricity measurement, roughness detector, projector, CMM, micro-meter, salt-spray device, etc.

High Efficiency

Asianstar turning-milling machines brings huge productivity, make the products by suitable one-time jig machine and in very fast speed

Competitive Price

Asianstar aim to buildup partnership with clients, always choose best suitable facilities to carry out the components in competitive prices

Components Sizes of Asianstar CNC Turning and Milling Service

| Unit (mm) | Min | Max |

|---|---|---|

| Out Diameter | 0.5 | 80 |

| Inner Diameter (Hole) | 0.3 | 75 |

| Length | 1.0 | 250 |

| Groove Diameter | 0.4 | above |

| Thread | M1.2 | above |

Components Tolerance of Asianstar CNC Turning and Milling Service

| Unit (mm) | Tolerance according to sizes | ||||||

| Height Tolerance | Diameter Size | 0.5 to 3 | 3 to 6 | 6 to 30 | 30 to 120 | 120 to300 | 300 to480 |

| Tolerance | ±0.003 | ±0.010 | ±0.020 | ±0.030 | ±0.035 | ±0.040 | |

| Length Tolerance | Length Size | 0.5 to 3 | 3 to 6 | 6 to 10 | 10 to 20 | 20 to 30 | 30 above |

| Tolerance | ±0.010 | ±0.020 | ±0.250 | ±0.250 | ±0.030 | ±0.035 | |

Components shape and position tolerance of Asianstar CNC Turning and Milling Service

| Tolerance Class followed | Tolerance (mm) | |||||||||||||

| Straightness and Flatness | Verticality | Symmetry | ||||||||||||

| 10 | 10 to 30 | 30 to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 | to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 | to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 | |

| H | ±0.015 | ±0.02 | ±0.03 | ±0.05 | ±0.10 | ±0.15 | ±0.02 | ±0.025 | ±0.03 | ±0.035 | ±0.02 | ±0.03 | ±0.04 | ±0.05 |

Capability of Asianstar CNC Turnnig and Milling Service

| Type of Machining Facilities | Diameter Size (mm) | Length Size (mm) | Productivity (PCS/Month) | |||

| Turning-Milling Machine | CNC Machining Center | Min 0.5 | Max 480 | Min 1.0 | Max 450 | 100’000/Item |

Asianstar CNC Turning and Milling Service Supports Various Industries Fields:

Most industries we are working for are as below(not limited to):