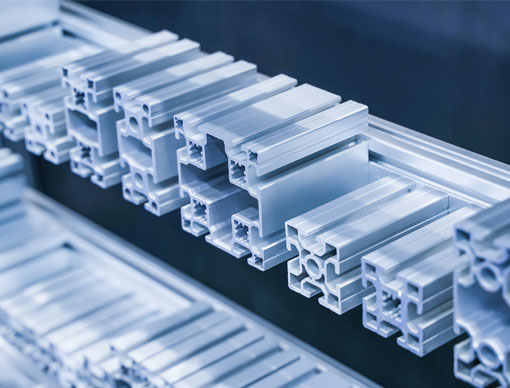

Aluminum Extrusion

Asianstar provide Aluminum Extrusion Service for worldwide clients at high precision, supporting various shape of designing.

What is Aluminum Extrusion

Aluminum extrusion is a process in which aluminum is heated and forced through a shaped opening, called a die or mold, to create a specific cross-sectional structure or profile.

This process allows for the creation of complex shapes and profiles with a high level of precision and consistency. It is very fast to bring the part into same structure in huge quantity.

The extruded aluminum is then cut to desired lengths and start CNC machining on it for extra more details demanded.

How Aluminum Extrusion benefits

Aluminum Extrusion brings continuous shape with the same profile as the die opening. This process is commonly used for producing complex profile in big quantity, it is rather fast to carry out the basic profile structure.

Aluminum Extrusion are used for:

1/ Automotive parts, such as frames, brackets, and suspension components

2/ Building and construction materials, such as door and window frames, and curtain wall systems

3/ Electrical components, such as electrical conduits and connectors

4/ Consumer products, such as sporting goods, furniture, and appliances

Aluminum Extrusion makes it a cost-effective and versatile manufacturing process for a wide range of applications.

Asianstar Professional Aluminum Extrusion

Asianstar is a leading manufacturer of aluminum extrusion parts for various industries. Our high-quality extrusion parts are used in a wide range of applications, including construction, automotive, aerospace, and more.

Our die mold technology supports extrusion process in high precision result.

We apply machining service on the work-piece after extrusion profile finished, and we also offer a variety of finishes and coatings to meet surface standards.

In addition to our standard extrusion parts, we also offer custom design and fabrication services. Our experienced engineers and technicians can work with you to create unique and customized solutions for your specific needs.

Advantages of Asianstar Aluminum Extrusion

Strong Die-Opening

Asianstar has ability and facilities to open high precision die opening, which much helpful for extrusion result in high precision and smooth surface

High Quality

Asianstar QC system and tools, gauges, pins, concentricity measurement, roughness detector, projector, CMM, micro-meter, salt-spray device, etc.

High Efficiency

Asianstar aluminum extrusion produce profile quickly by tons, our abundant CNC machines for fast machining after extrusion professionally

Competitive Price

Asianstar aim to buildup partnership with clients, always choose best suitable facilities to carry out the components in competitive prices

Components Sizes of Asianstar Aluminum Extrusion

| Unit (mm) | Min | Max |

|---|---|---|

| Width | 5 | 250 |

| Length | 5 | none limited |

| Height | 5 | 250 |

| Sides | 1 | 6 |

Components Tolerance of Asianstar Aluminum Extrusion

| Unit (mm) | Tolerance according to sizes | |||

| Width/Height Tolerance | Width/Height Size | 5 to 20 | 20 to 50 | 50 above |

| Tolerance | ±0.015 | ±0.02 | ±0.03 | |

Components shape and position tolerance of Asianstar Aluminum Extrusion

| Tolerance Class followed | Tolerance (mm) | |||||||||||||

| Straightness and Flatness | Verticality | Symmetry | ||||||||||||

| 10 | 10 to 30 | 30 to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 | to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 | to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 | |

| H | ±0.015 | ±0.02 | ±0.03 | ±0.05 | ±0.10 | ±0.15 | ±0.02 | ±0.025 | ±0.03 | ±0.035 | ±0.02 | ±0.03 | ±0.04 | ±0.05 |

Capability of Asianstar Aluminum Extrusion

| Facilities of Aluminum Extrusion Parts | Height Size (mm) | Length Size (mm) | Productivity (PCS/Month) | ||||

| CNC Machines for Die Opening | Cutting Machine on Aluminum Profile | Bending Machine after cutting | Min 5 | Max 250 | Min 5 | above | 300’000/Item |

Asianstar Aluminum Extrusion Supports Various Industries Fields:

Most industries we are working for are as below(not limited to):