Yes, we support ODM/OEM, we provide custom-made service for clients or even support clients on designing or improving

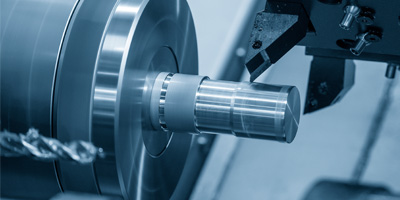

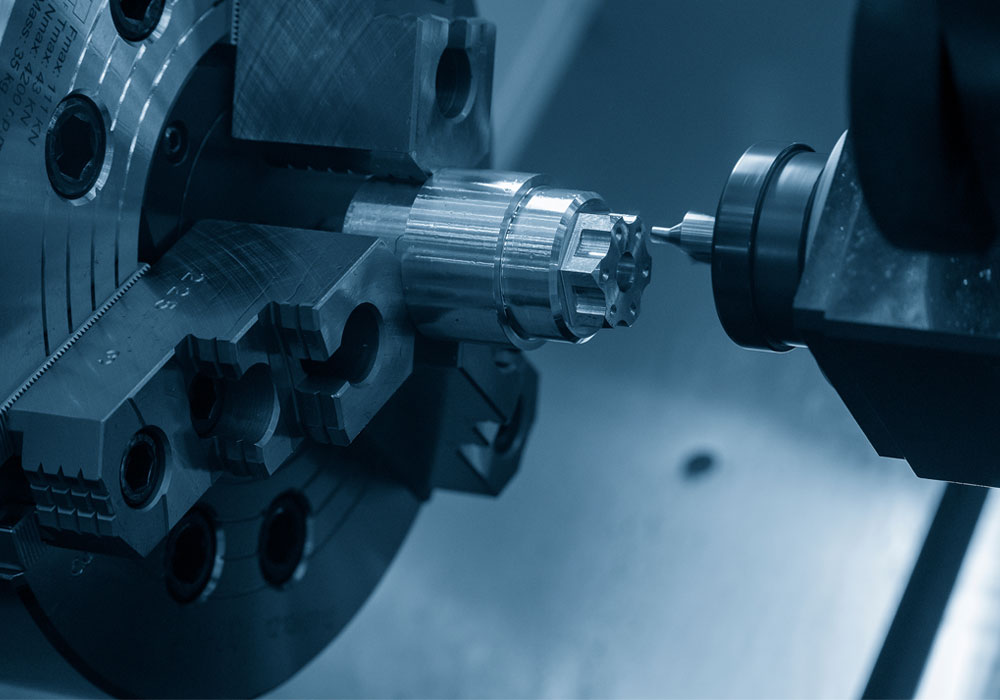

PROFESSIONAL CNC MACHIING SERVICES

Asianstar is a professional CNC machining services supplier, we are highly appreciated by our plentiful facilities, multi processes and skillful team.

CNC MACHINING SERVICE

CNC machining is a manufacturing process that involves the use of

computer numerically controlled (CNC) machines to cut materials to

create parts and components with high precision and accuracy.

CNC Machining Service supports companies to create a wide range of

parts and components for a variety of industries, including aerospace,

automotive, medical, and more.

Normally the machining services are working on metal materials and

plastic materials.

CNC MACHINING SERVICE FROM ASIANSTAR

Asianstar offers CNC machining services for a variety of materials, including metals and plastics. Our skilled engineers use suitable CNC machines to produce high-quality parts with precision and accuracy.

We can work with clients ideas or existing designs or even creating custom designs to meet clients specific needs. Our services include milling, turning, drilling, grinding, tapping, forming, and rolling, and we can handle a range of tolerances as strict as 0.003mm and various surface finishes.

Also, we have sheet metal fabrication service, aluminum extrusion service, forging service, such service allow us to provide more supporting to our clients and help clients to develop more functions components. We are offering prototyping and mass-volume production services. Our team is experienced to provide excellent CNC machining services and quick lead-time to our clients.

ADVANTAGE OF ASIANSTAR CNC MACHINING SERVICE

OUR CNC MACHINING SERVICES

ASIANSTAR CNC MACHINING SERVICES SUPPORT CLIENTS FROM VARIOUS INDUSTRIES FIELDS:

Most industries we are working for are as below(not limited to):

FAQ GUIDE

-

Q1.Do you support ODM/OEM?

-

Q2.Do You Have Stock

-

Q3.What Is Your Production Capacity?

-

Q4.Where Is Your Factory?

-

Q5.Can You Provide Samples?

-

Q6.How About Your After-sales Service?