CNC Steel Machining

Asianstar provides CNC Machining Steel Parts by multi processes, we produce series steel parts for wide ranges of industries.

CNC Steel Machining

CNC Machining Steel Parts are one of the most common parts in wide fields.

With its high hardness and strong features, many devices and industries are using different kinds of steel as their key parts.

CNC machining steel parts are mostly using mild steel and carbon steel, with their features of machinability and plasticity.

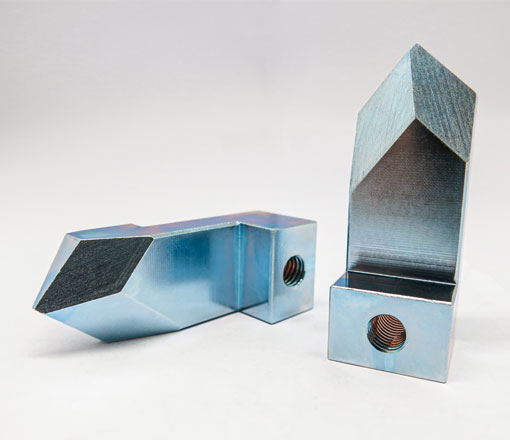

Therefor, steel series parts are machined by many kinds of processes, the processes on steel series materials include CNC turning, milling, threading, forming, casting, forging, wire cutting, fabrication, etc.

Steel parts are mostly needed with hard-strong feature and long duration, it needs surface finishing to resist against rust.

Benefits of CNC Steel Machining

1/ CNC machining steel parts are widely used for many industries because of strong feature

2/ CNC machining steel parts are long time durable with high resistance and high density

3/ CNC machining steel parts are flexible for production because it can be handled by many different processes

4/ CNC machining steel parts are great for post treatment or extending treatment, such as heat harden, enhance its ability

5/ CNC machining steel parts are good at cost, its material price is cheap and allow large using

6/ Steel parts is basically environmental material and supporting recycle collecting, benefits the burden of world

Asianstar Professional CNC Machining Steel Parts

Asianstar is a professional top-grade CNC machining manufacturer in steel parts.

We have ability to use multi machining processes on steel parts production. With our various facilities, we can choose different machines and solutions to produce parts according to parts usage purpose. We use cutting, wire cutting, turning, milling, forging, fabrication, welding, etc. processes on steel parts production.

The surface finishing treatment on CNC machining steel parts are also abundant, we normally choose coating finishing or oil protecting to avoid rust, and choose other finishing to increase steel parts appearance.

Advantages of Asianstar CNC Steel Machining

Strong Facilities

Asianstar many CNC machines allow us to produce various steel parts, different shapes, sizes, and structures are all well done by suitable solution

Long-term Skills

Asianstar professional engineers team has experience from year 2005, we produce many steel parts for world wide clients and gain more skills

Stable Quality

Asianstar QC system and QC tools guarantee our products are perfect result. We have procedures to control steel parts quality during production

Competitive Price

Asianstar aim to buildup partnership with clients, always choose best suitable facilities to carry out the components in competitive prices

Composition And Property of CNC Machining Steel

| Steel Property | Alloy Type | Content | Melting Point | Hardness | Tensile Strength | Density |

| Iron-Carbon | Ferrum, Carbon and others | 1538 °C | HV 120-180 | 235 MPa | 7.85 g/cm3 |

Common Materials Code of CNC Machining Steel

| Steel Alloy | Workable Processes | Surface Finishing for Steel Parts | Materials Code |

| CNC Turning, CNC Milling, CNC Drilling, Molding, Forging, Fabrication, Stamping, Welding, Casting, etc. | Platinig, Passivation, Nitriding, Phosphating, Blasting, Painting, Powder, etc. | Steel 1215 | |

| Steel 4140 | |||

| Steel 4143 | |||

| Steel FC300 | |||

| Mid Steel | |||

| other more Steel Alloy |