If you ever wondered what flakes off of forged metal, or why some people wear tinfoil hats, then this is the article for you

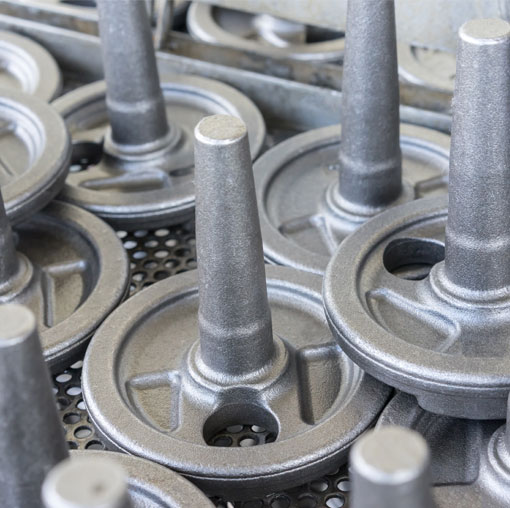

A forged metal surface is a number of things. It's an alloy that has been melted down, cooled, and then rolled into a flat sheet. The shape of the sheet changes as it cools and hardens, but there are some pretty consistent rules about how it will behave

The first thing to understand is that forged metals can have defects in their properties that can cause problems for machinists when they work with them. For example, a forging that has too much carbon in it will not be as strong as one with less carbon in it. A forging with too much hardness will also weaken under stress, so if you want your parts to withstand stress without breaking then you need to make sure there's enough carbon present in your metal to give it the right balance between strength and hardness

Over time these defects build up until they become so severe that they make working with the material impossible or at least very difficult. When this happens it's called flaking or peeling because pieces of the material just flake off when they're worked on by machinists who don't know any

what flakes off of forged metal