Plastic nails are an essential part of your CNC machine and are used for creating precise parts

Plastic nails have been around for a long time, but they have recently become more popular in the industry because they are easier to use than metal nails. They are also more durable, as they are made from a stronger plastic material than metal nails

The most common type of plastic nail is the self-tapping plastic nail, which is used when drilling holes in wood or metal. These plastic nails will require you to drill into them with a drill bit before they can be used in your machine.

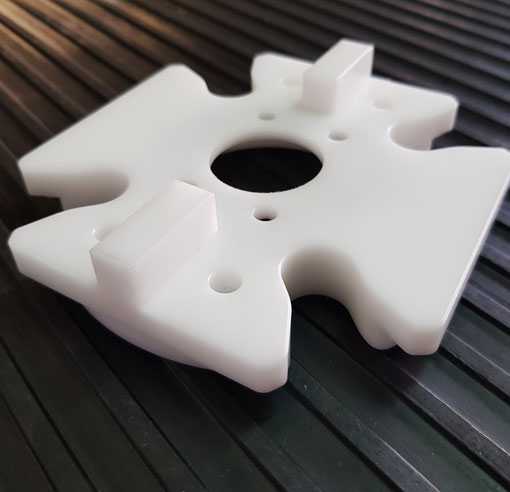

plastic nails for cnc